Organizational Units of the Faculty of Engineering in Pula

The Faculty of Engineering in Pula consists of the following organizational units:

-

Laboratory for Automation and Robotics

-

Laboratory for Electronics and Electrical Engineering

-

Laboratory for Energy Systems and Renewable Energy Sources

-

Laboratory for Software Engineering and Data Processing

-

Laboratory for Robotics and Artificial Intelligence

-

Laboratory for Technical Measurements and Joining Techniques

-

Laboratory for Thermodynamics and Thermal Engineering

Scientific Research at the Faculty

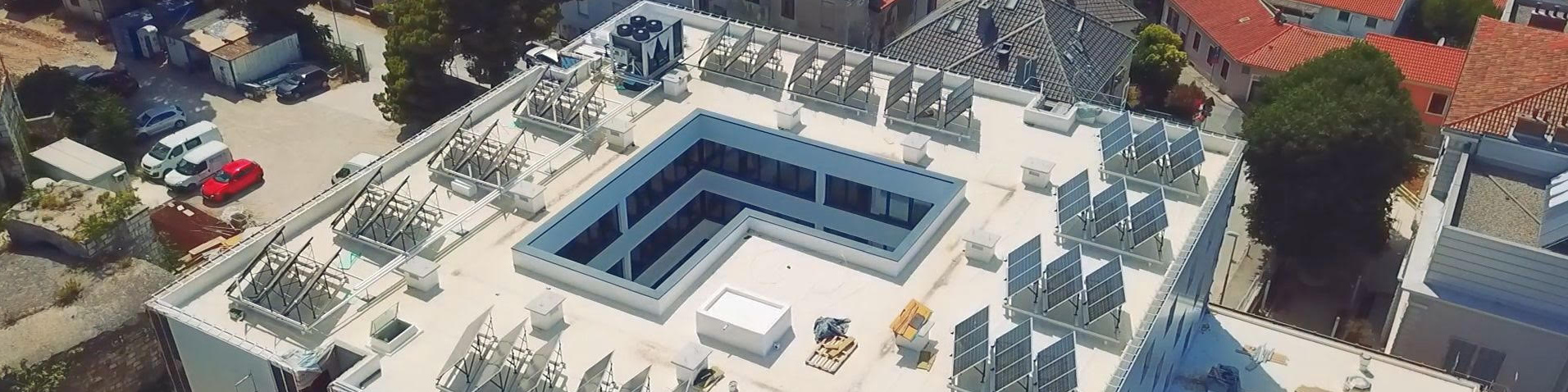

The Faculty conducts scientific research across various technical disciplines. One key area involves renewable energy sources, such as photovoltaic systems and wind turbines, which provide alternatives to the daily use of conventional energy. Research on the thermal conversion of solar energy explores the replacement of traditional thermal energy sources used in households, industry, and tourism.

In addition to renewable energy, the Faculty also conducts research on signal processing from biological systems. This involves developing the mathematical foundation, implementing algorithms, analyzing results from both synthetic and real signals, and creating a virtual instrument intended for users without prior knowledge of signal processing.

Additive Technologies

Additive manufacturing technologies (e.g., 3D printing) are increasingly used globally and have become essential tools for producing functional prototypes during product research and development across sectors such as automotive, shipbuilding, construction, and healthcare. Despite their advantages, these technologies have limitations, including size constraints of printed models, long production times, and high material costs.

To optimize the 3D printing process, one research focus at the Faculty involves combining robotic modules with FDM 3D printing heads.

Smart Manufacturing and Workplace Safety

Modern manufacturing systems enhance machine performance and production efficiency through innovative solutions. This requires planning not only for functionality and durability but also for the interaction of translational and rotational machine components, and potential workplace hazards. Issues such as increased vibration, noise, light reflection, and heat may negatively impact workers' health.

To address this, the Faculty is developing intelligent manufacturing systems tailored to human physiological parameters. A current research project aims to create a method and software solution for continuously monitoring physical hazards during both planning and production phases. The system includes sound pressure level monitoring and protection through octave band analysis.

Sheet Metal Forming

Another area of research involves modeling sheet metal forming processes. The goal is to develop a diagnostic software solution based on laboratory and field test data. Objectives include identifying and resolving production issues and conceptually planning the use of new materials. The research also aims to enhance understanding of material behavior with selected tool systems, ultimately improving precision in product fabrication. The results will support the metal processing industry by optimizing tool usage and increasing machine productivity and competitiveness.

Multi-Agent Systems

Multi-agent systems offer improved efficiency through parallel task execution, distributed architecture, robustness, and scalability. However, managing such systems requires appropriate coordination algorithms. Achieving common goals and system stability involves defining coordination rules among potentially large numbers of autonomous agents, often resulting in complex behavior.

A key research goal at the Faculty is to develop decentralized control algorithms for multi-agent systems and identify global connectivity patterns within their communication networks. These solutions could be applied in real-world scenarios such as industrial robot management, traffic systems, or sensor networks.

Interdisciplinary Research: Startup Growth Modeling

The Faculty also participates in an interdisciplinary project focused on developing computer models for the growth of technology startup companies and creating an interactive educational simulator for startup entrepreneurship, known as ILE4Tech.

Scientific Conferences

Scientific Projects

Faculty members have participated or are currently involved in the following research projects as project leaders, researchers, and/or collaborators:

-

Intelligent systems for measuring and controlling physical hazards in production processes

-

Engineering of complex software systems in evolution

-

Feature extraction from signals generated by biological systems

-

Heat exchangers in renewable energy systems – compact heat exchangers

-

Optimization of additive manufacturing technologies using robotic arm systems

-

Development of control algorithms for decentralized multi-agent systems

-

Development of automated methods for sheet metal forming process modeling

-

Computational models of technological startup companies

-

Systems and components for renewable energy – photovoltaic systems and electrical conversion

-

Systems and components for renewable energy – thermal conversion

-

Systems and components for renewable energy – wind turbines

Pristupačnost

Pristupačnost